Envirotech delivered an upgrade to the generator suite, modernising low‑voltage distribution, generator controls and protection while coordinating supporting ventilation changes. Working within an operational building, the team sequenced changeovers to keep resilience in place and maintain safe access during all works.

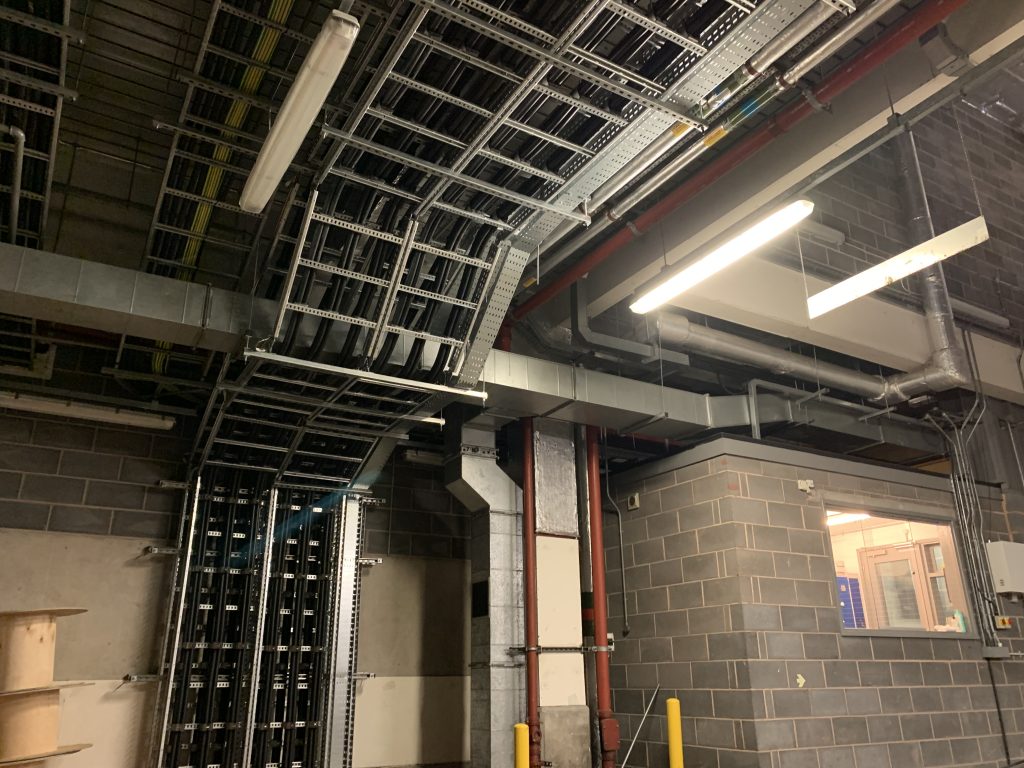

The electrical scope formed the backbone of the project. Envirotech designed, supplied, installed and set to work modifications to the LV distribution and standby generator control architecture, rationalising supplies and providing clear segregation for maintenance.

A new MCP 6 control panel was installed in the standby generator room at B3 level to centralise control and alarm/status monitoring. The package included new small‑power and lighting to suit the revised layout, comprehensive earthing and bonding, and lightning and surge protection to safeguard sensitive equipment. Supporting the electrical works, the mechanical scope provided compliant ventilation to the generator room with new supply and extract fans sized for standby and test conditions. Existing supply, extract and smoke‑vent routes were re‑routed to create a new FM office in the former generator space, maintaining appropriate airflow and smoke clearance while rationalising the plant layout.

Commissioning and witness testing focused on proving the MCP 6 control logic, generator changeover sequences, alarm paths and interlocks, alongside validation of metering and protective devices. Airflow performance was demonstrated for both generator and FM office modes. Records, including functional test results, inspection reports and certification, were issued at close‑out to complete a fully verified installation